What is an underfloor heating manifol? Brass vs. Stainless Steel Manifolds: Which is Best for Your Heating System?

Choosing between a brass manifold and a stainless steel manifold for your heating system depends on various factors such as budget, durability, and specific requirements.

Here’s a comparison to help you decide:

Brass Manifold:

Brass manifold – complete kit – Grundfos / Wilo pump pack – The Underfloor Heating Expert

1. Cost: Brass manifolds are often more affordable compared to stainless steel manifolds.

2. Corrosion Resistance: Brass is resistant to corrosion, making it suitable for most residential applications.

3. Thermal Conductivity: Brass has good thermal conductivity, which helps in efficient heat distribution.

4. Ease of Installation: Brass manifolds are relatively easy to install and work with.

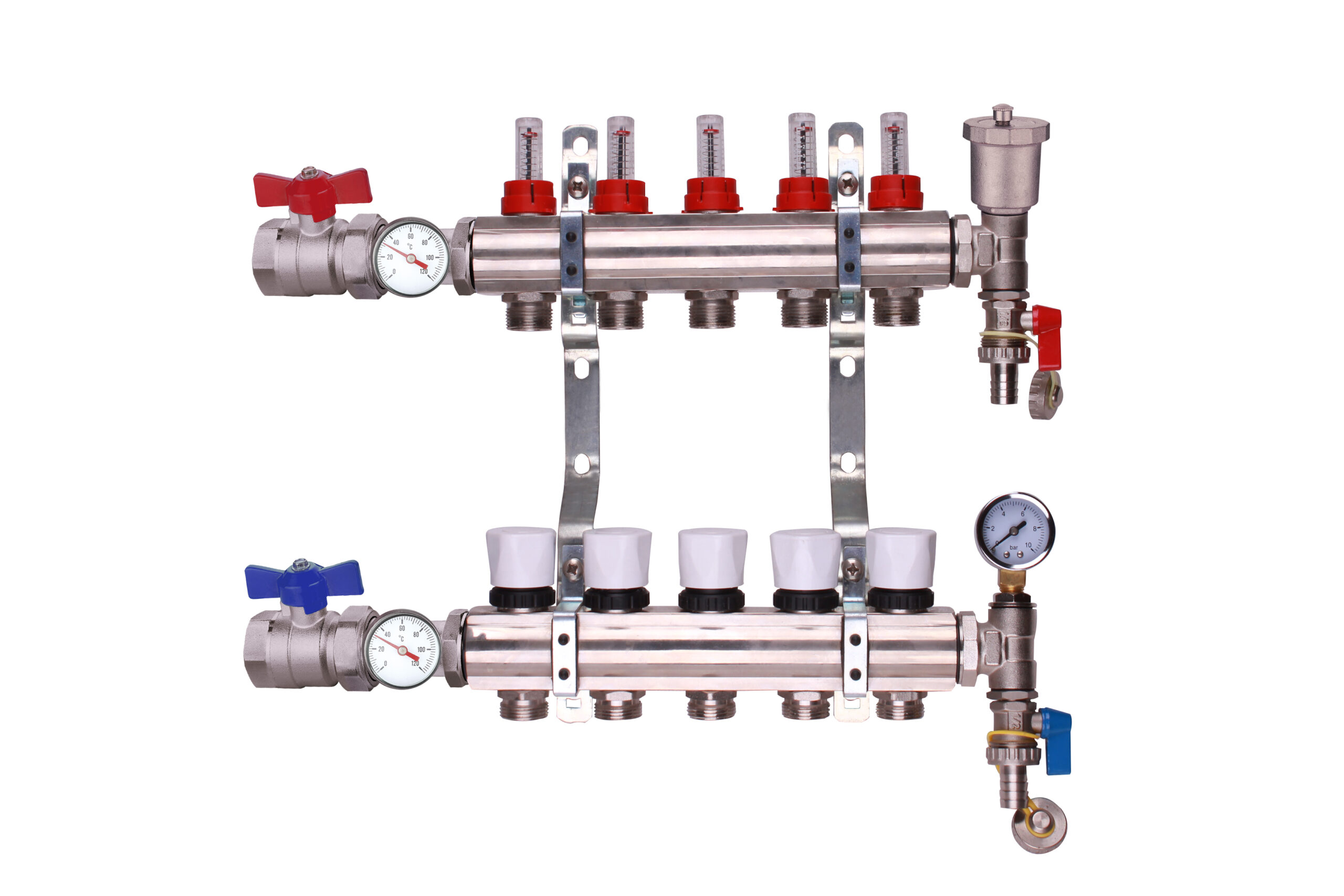

Stainless Steel Manifold:

Stainless steel manifold – complete kit – Grundfos / Wilo pump pack – The Underfloor Heating Expert

1. Cost: Stainless steel manifolds are generally more expensive than brass ones.

2. Corrosion Resistance: Stainless steel is highly resistant to corrosion and rust, making it ideal for harsh environments and long-term use.

3. Strength and Durability: Stainless steel is stronger and more durable than brass, offering a longer lifespan and better reliability.

4. Hygienic: Stainless steel is non-corrosive and non-reactive, making it suitable for use in potable water systems.

5. Appearance: Stainless steel has a sleek and modern appearance, which may be preferable for some installations.

Ultimately, the choice between brass and stainless steel manifold depends on your specific needs, budget, and preferences. If corrosion resistance and longevity are top priorities, stainless steel may be the better option despite the higher initial cost.

However, if cost-effectiveness is more important and the environment is not overly corrosive, brass could be a suitable choice.