Why choose underfloor heating? Top Tips for Underfloor Heating System Installation

Planning Underfloor Heating

Why choose underfloor heating?

This question marks the beginning of the entire journey in selecting heating for a future home or apartment. We answer that it’s an economical and ecological choice. To fully understand what underfloor heating is, it’s worth breaking it down into two main types:

- Underfloor heating in traditional construction (with concrete or screed) used in newly built homes.

- Underfloor heating in dry construction – done in renovated houses or on the floors of wooden houses.

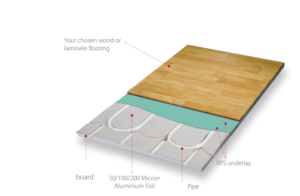

Dry construction underfloor heating system

Dry construction underfloor heating is dedicated to renovations, timber frame construction, and wherever traditional underfloor heating cannot be installed (adding heavy screed is not possible). Commonly known as dry underfloor heating, it consists of boards, so-called base layers (e.g., made of polystyrene). These boards have grooves in their structure where the pipe is fixed. Additionally, the boards are covered with an aluminium radiator, which facilitates the distribution of heat.

The finishing of the floor itself (wood, wood-based panels, ceramics, and other finishing elements) is done directly on the dry construction underfloor heating.

Of course, screeds can be applied to this type of heating, but there is not always room for that during renovations.

It’s important to note that underfloor heating boards, e.g., made of polystyrene, should be selected in EPS 300 or 400 class, which are very resistant to compression, while the board made of compressed wood fibre ideally soundproofs the room (damps acoustic vibrations) – it’s worth remembering this if the investor cares about acoustics.

Traditional construction underfloor heating

We can divide underfloor heating in traditional construction into several subcategories: installation using clips, mounting rails, or using egg crate panels where the pipes are embedded in the concrete screed. This type of heating, thanks to its specification, works perfectly during new investments, providing economical and invisible heat sources.

Technical development of underfloor heating

To start the process of creating underfloor heating, you need to begin with technical development. It’s worth using available online tools at the beginning, which will provide an estimate of heating. An example is an underfloor heating calculator, which guides the future investor step by step through the underfloor heating process and preliminarily outlines an offer for the selected system and floor area.

To start the process of creating underfloor heating at home, you need to properly prepare the substrate and insulate. Appropriate insulation should be applied, consisting of a double layer of EPS 200 polystyrene (the first layer was created to hide pipes of other water and sewage installations, while the second layer is the top layer for underfloor heating).

Edge tape

It’s worth also protecting the underfloor heating with edge tape, which serves as expansion joints for thermal expansion of the screed. This type of expansion joint is applied by sticking it to the walls, hence it’s called edge tape or edge expansion. In traditional systems, the expansion tape is slightly higher than in dry construction systems.

Location of manifold

Another essential element in underfloor heating is the manifold or rather the place where the manifold is located.

Underfloor heating pipes

In underfloor heating, two types of pipes can be used: PERT-AL-PERT or PERT-EVOH-PERT.

200m Pert EVOH 16mm Pipe – The Underfloor Heating Expert

The PERT-EVOH-PERT pipe is a 5-layer pipe. The name EVOH is a type of ethylene-vinyl alcohol copolymer and serves as a diffusion barrier (protects against the penetration of oxygen into the water). The presence of oxygen in the water would cause the growth of bacteria and the appearance of sludge over time. To prevent such a situation, it’s also worth using water treatment chemistry -separator. This pipe has shape memory because after bending, it does not return to its previous shape.

PERT-AL.-PERT is also a 5-layer pipe (excluding the adhesive bonding layers, there are only 3 layers). This type of pipe with an aluminium layer is called a universal pipe. Pipes are called pipes with shape memory, it does not return to its previous shape.

200m Pert Al Pert 16mm x 2mm pipe – The Underfloor Heating Expert

Egg Crate Castellated panels

Can be used for the installation of underfloor heating pipes. It is distinguished by so-called ribbing, which is located between the protrusions. This ribbing causes the pipe placed on such a mat to be minimally spaced from the substrate. If such a pipe is spaced, floor substrates called screeds, which are fluid, warm, self-levelling, envelop the pipe. TThe protrusions on the mat are built in such a way that they have additional protrusions on all 4 sides. Additional elements at the protrusions provide better anchoring of the pipe (which prevents the pipe from jumping out during installation).

Castellated egg crate panel for 15/16mm pipe – The Underfloor Heating Expert

Unwinding Underfloor Heating Pipes

A so-called pipe unwinder is used to unwind pipes for underfloor heating, which unwinds pipes from coils of 100 and 300 meters (depending on the unwinder, the length of the coils may vary). PEX or PERT pipes for underfloor heating are wound onto coils during production, which gives them tension by default. During unwinding on a metal unwinder – pipe decoiler, the underfloor heating pipe is relaxed and does not behave like a spring, making it easier for the installer.

Pipe Decoiler – The Underfloor Heating Expert

Gas Boiler for Underfloor Heating

The boiler is an essential element of underfloor heating and is the central heating device. Boiler uses natural gas for combustion, and single-functionality means that it heats only boiler water, i.e. The heating factor that we have in a given installation, and only then is the hot water in the hot water tank heated.

In large houses, it’s also worth having integrated mixing systems with hydraulic coupling in the boiler room. This allows for the management of even several heating circuits in underfloor heating, which gives the possibility of parameterizing the water temperature in the installation independently. In the case of large houses, some rooms heat up faster than others due to different building exposures.